Ever wish you had a spreadsheet to help understand the economics of a 3D printer purchase? Here you go.

Identifying the relevant cost parameters and calculating the Return on Investment (ROI), Internal Rate of Return (IRR) or the breakeven point can be an important part of the decision process. This spreadsheet is completely editable, so you can easily modify it to fit your situation.

In addition to a great ROI, a stron IRR, or a short breakeven point, there are many other benefits that make 3D printing attractive. For example, with 3D printing, you can:

— Quickly and inexpensively iterate on your design,

— Reduce or eliminate design errors,

— Shorten lead times for products and tooling, and

— Decrease your time to market.

Such strategic advantages are real and more difficult to quantify. Even though they aren’t included in this spreadsheet, you’ll obviously want to include them in the decision process.

Overview of the Spreadsheet (Financial Model)

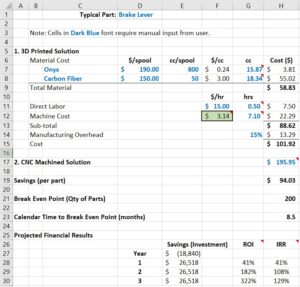

When you open the spreadsheet, you’ll find a note near the top that states that cells in dark blue font require user input. These cells need to be reviewed and, if necessary, modified to fit your scenario. They are already populated with values that reflect the case study below. The labor rate, manufacturing overhead rate, and the build parameters for your part will likely be different. By simply modifying the appropriate cells, you can customize the model to assess the business case for your situation.

A Case Study – A Motorcycle Brake Lever: 3D Printed vs. CNC Machined

In this example, we’ve assumed that a motorcycle brake lever is a “typical part” that represents the size and complexity of the parts you expect to build if you purchase the 3D printer.

Step 1 – Estimate the cost of 3D Printing the Part.

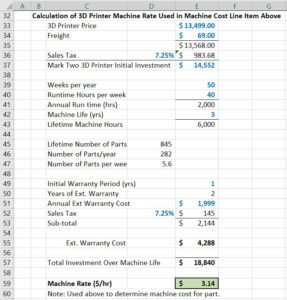

This case is based on the purchase of a Markforged Mark Two 3D printer for $13,499 plus freight and sales tax. While we’ve seen cases of 3D printers running five years and even ten years, we’ve conservatively assumed a three-year life for the 3D printer. We assumed it will be used 40 hours/week for 50 weeks per year. This unit comes with a one-year warranty, and we’ve assumed that an extended warranty will be purchased for years 2 and 3 at the manufacturer’s price of $1,999 per year. We estimated a half hour of labor at $15.00/hr, and we used a Manufacturing Overhead rate of 15% and a Sales Tax rate of 7.25%.

Like many slicing software applications, Markforged’s Eiger software provides estimates of the build time and material usage. We used Onyx for the plastic, and to achieve the desired strength for this part, we embedded carbon fiber. A screen shot from the Eiger software is provided below (click image to enlarge), and the values circled in yellow have been entered into the spreadsheet. Material prices are available from Markforged.

Step 2 – Determine the cost for CNC machining the part.

For the CNC machined approach, we used cost information from an outside service to fabricate the part out of aluminum, which is $195.95.

Step 3 – Calculate the costs, savings, breakeven point, and ROI.

An image from the spreadsheet is shown below (click image to enlarge).

For completeness, the supporting details that were used to determine the hourly machine rate for the 3D printer ($3.14/hr) are provided in the image below (click image to enlarge).

Results

A summary of the results for this case study shows:

1. 3D Printing saves $94.03 per part compared to CNC machining,

2. The breakeven point occurs when 200 parts have been 3D printed,

3. The calendar time to reach the breakeven point is 8.5 months, and

4. The ROI for Years 1, 2 and 3 is 41%, 182%, and 322%, respectively.

5. The IRR for Years 1, 2, and 3 is 41%, 108% and 129%, respectively.

If you find errors or have questions, please let us know. If you’ve found this financial tool to be helpful, we welcome that feedback too and encourage you to share this with others. We provide 3D printers, 3D scanners, and 3D printing services. Learn more.