Dive into reverse engineering!

Video 1: How to Use the EinScan Pro HD for Reverse Engineering

Video 2: How to use Design X for Reverse Engineering

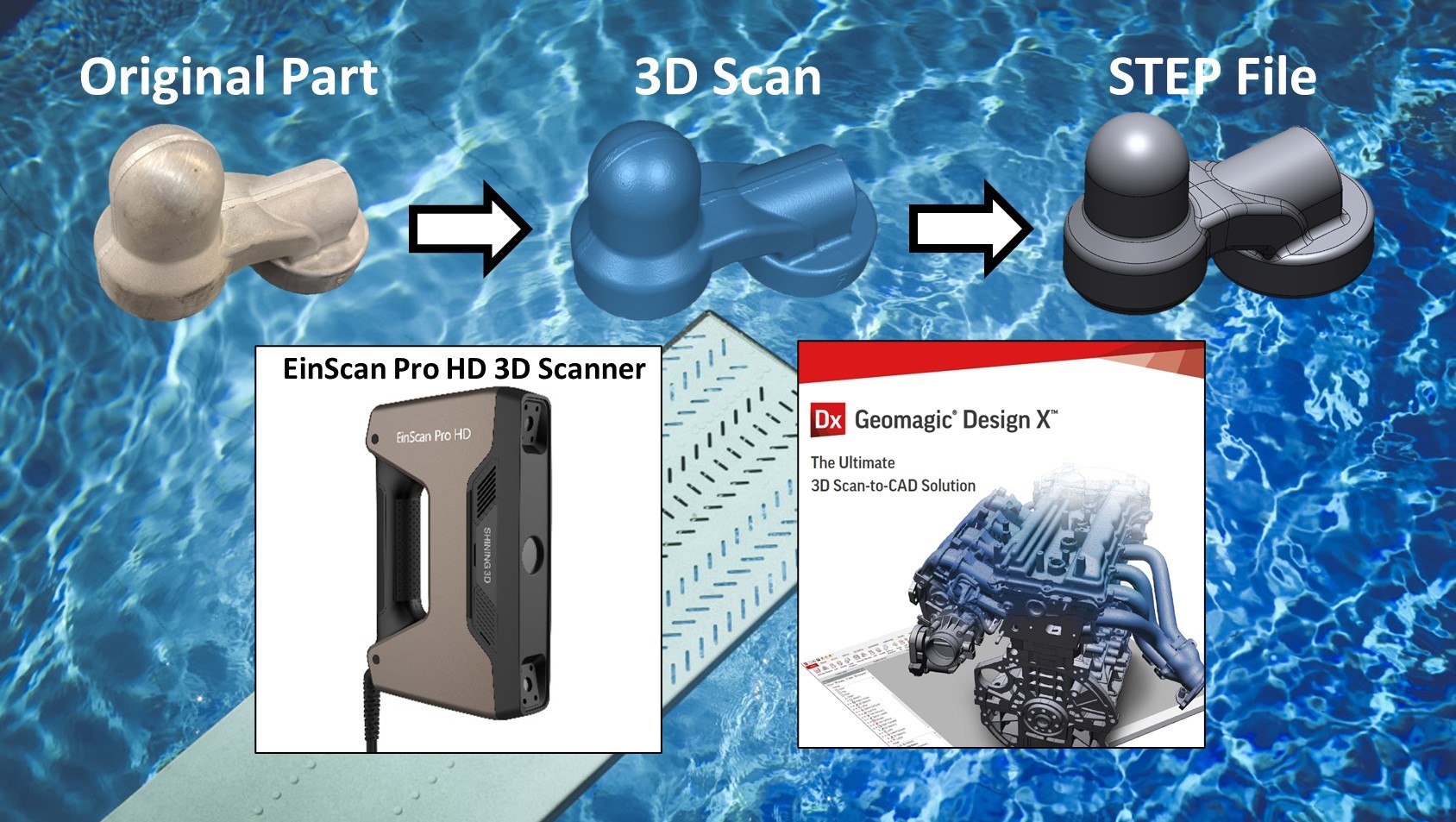

View these two videos for in in-depth, step-by-step tutorial on how to use the EinScan HD Pro 3D scanner and Geomagic Design X software. Using these robust tools, the actual time required to go from an original part to an editable CAD file was 1 hour and 10 minutes.

Learn more about these products at the links below.

EinScan Pro HD 3D Scanner

Geomagic Design X

Both of these tools are high-end, professional grade, and robust. You’ll see how quickly you can 3D scan the item and align the scan to your global axes. With the scan aligned, you can quickly and simply extract information from the 3D scan to create an editable CAD (computer aided design) file. You may be documenting an existing design or using this new 3D model as a starting point for developing your next product. In either case, you’ll be reducing design time, increasing the opportunity for additional design iterations, and ultimately shortening the time to market.

Can reverse engineering be performed without such powerful tools? Yes, but not with the same speed, efficiency, and accuracy. It’s a bit cliché to say that time is money, but we all know that to be the case. The sooner you knock out that reverse engineering task, the sooner you’ll be able to use the resulting 3D model in your workflow.

The example provided in these videos is fairly straightforward in that it involved the creation of four features that are all prismatic. Imagine what would be required to reverse engineer the propeller shown to the right. We’ll tackle that in a future post, but feel free to contact us if you have questions now.

At Strategic 3D Solutions, we partner with customers to provide solutions every day. Need help with designing, 3D printing, or 3D scanning for your project? Planning to purchase a 3D printer or 3D scanner? Contact us.