Metal plating 3D printed parts is effective for making replicas of rare and historic artifacts.

This post shows the process of using 3D scanning, 3D printing, and metal plating to make replicas of artifacts. In this case, we provided replicas of the original brass plaque below to meet our client’s needs.

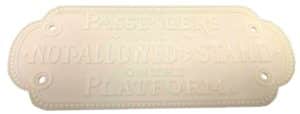

The original brass plaque used on a passenger rail car (circa 1880’s).

The result: a brass plated 3D printed plaque.

The Challenge

One of our clients, McDowell Engineers and Associates, works with the North Carolina Department of Transportation (NCDOT). They needed replicas of a brass plaque from a vintage passenger rail car. Officials decommissioned the rail car in 1937. In that era, officials mounted such plaques on the end doors of passenger cars. Standing on an open vestibule while the car was in motion was dangerous. The plaque’s design and quality reflect how important rail travel was at the turn of the 20th century. The current rail car owner purchased it in 1956 and converted it into the Midway Diner in Sedalia, NC that operated into the 1960’s.

The replica plaques will be used in an exhibit at the North Carolina Transportation Museum. In identifying the best solution to fabricate replicas, McDowell established the key criteria. They were: 1) low risk of damage to the original, 2) accuracy of the replica, and 3) keeping the work in North Carolina.

The Solution: 3D Scanning, 3D Printing, and Metal Plating

First, we used the Geomagic Capture 3D Scanner and Design X Software to 3D scan the original brass plaque. See image below of the scanned data.

3D scanned data from the Capture Scanner and Design X Software.

Then, we created an editable 3D model in Design X using the scanned data as reference information. Design X has a robust set of features and capabilities. We developed the 3D model and exported an STL file for 3D printing. See below.

3D model of the plaque from Design X Software.

Next, we selected our EnvisionTEC Ultra 3SP 3D Printer to make the plaque. Why? EnvisionTEC 3D printers provide world-class accuracy and surface finish. And we used ABS Tough material and 50 micron layers to achieve great results. See below.

3D printed plaque fabricated on an EnvisionTEC Ultra 3SP.

Lastly, we had the 3D printed plaques brass plated. See below.

Brass Plated 3D Printed Plaque. Simply beautiful.

With that successful outcome in hand, McDowell and NCDOT ordered three more, and we delivered them to complete the project.

Summary

In conclusion, we metal plated 3D printed plaques to create accurate replicas without damaging the original. We successfully provided a solution that met all of our client’s criteria.

At Strategic 3D Solutions, we partner with customers to provide solutions every day. Need help with designing, 3D printing, or 3D scanning for your project? Planning to purchase a 3D printer or 3D scanner? Contact us.