Markforged 3D Printed Tooling and Fixtures

Key Benefits of 3D Printed Tooling and Fixtures

- Reduce Lead Time

- Decrease Cost

- Improve Uptime

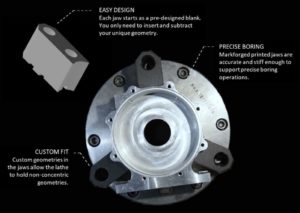

3D printing is great for prototypes and end use production parts, and it’s also the perfect solution for making fixtures and tooling for the machine shop. Markforged has estimated that 40% of their customers are using Markforged 3D printers to make fixtures and tooling for a number of manufacturing processes.

Why Markforged?

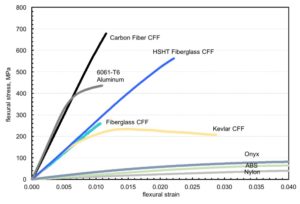

Quite simply, because Markforged printers build strong parts with excellent dimensional stability. In the early days of Markforged, they only offered nylon. But in 2016, Markforged launched Onyx, which is comprised of nylon with chopped carbon fiber. Onyx provides about twice the strength and stiffness of nylon, and the surface finish of Onyx is better.

Are you looking for even more strength? Markforged provides a unique feature in the 3D printer market: the ability to embed a continuous fiber inside the plastic part. And not just any fiber, but several fiber choices (carbon fiber, Kevlar, fiberglass, and high strength high temp fiberglass) to fit a variety of applications.

How strong are these parts? The strength-to-weight ratio can exceed that of 6061 Al, as shown in the figure below.

Click to Enlarge

Case Studies: 3D Printed Tooling and Fixtures

As you might have guessed, many are already reaping the rewards by using Markforged to make their tooling and fixtures. Want to review case studies on 3D printed tooling and fixtures? Click the links below.

Video Case Studies

Written Case Studies

Markforged Stands Out on the Unilver Factory Floor

The Mark Two Secures a Firm Grip in Robotic Automation

Reinforced Modular Fixtures Brings the Handmade French Horn Within Reach

Markforged Nylon: A Resistant Solution

Conquering Hurdles in Fabrication with the Mark One

Speeding Up Processes Everywhere with the Mark One