Top Two Applications for 3D Scanning

Reverse Engineering | Quality Assurance

Reverse Engineering

Reverse engineering is the process of extracting design data from a product and reproducing it or a variation of it.

Some may tend to think of this in the context of creating designs of a competitor’s products, but that’s not our focus. Reverse engineering may be needed to update the design drawings to match the product being made. In other cases, spare parts don’t exist or drawings have been lost. One can greatly reduce the time and effort needed to re-create the design with the aid of 3D scanning. Further, the impact is even stronger for more complex parts. Detailed features and organic shapes are difficult and time consuming to measure with traditional tools (e.g. scales, calipers). 3D scanned data enables designers to rapidly create a 3D model of the object.

Interested in seeing how Jay Leno’s Garage uses 3D scanning and Geomagic Design X software? Click here.

Jay Leno’s 1916 Owen Magnetic, one of the first hybrid electric cars.

Quality Assurance

Quality Assurance (QA) involves the methods used to verify that products meet their specs. The scope of the QA function depends on the nature of the products and the build processes. For many products, evaluating the dimensional integrity of the product is of great importance. However, assessing the dimensions of a product using traditional methods can be time intensive and in some cases, nearly impossible.

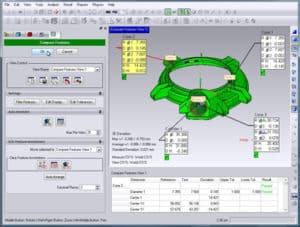

With the right 3D scanning software, designers can compare 3D scanned data to the design model. Additionally, color maps enable users to quickly view problem areas. Users can even choose any point on the color map to see the precise errors at that location. Further, the 3D scanning process for a given part number can be captured, stored, and used on each part produced. Lastly, by analyzing stored data on many parts over time, engineers can observe trends and take action if needed.

Want to see how Schneider Electric has used 3D scanning in their QA process? Click here.

Screen shot from Geomagic Control X software used by Schneider Electric.

Strategic 3D Solutions provides 3D printers, 3D scanners, 3D printing services, 3D scanning services, and design services.